Power Modules

Power Modules

Heritage

- Three phase bridge

- Half bridge switch

- Full bridge switch

- Boost converter

- Buck converter

- Double forward converter

- Thrust vector controls

- Improved Performance - discrete components are tested at full current / power ratings and can be selected for matched performance prior to PM assembly

- Improved Reliability - uses prescreened & qualified components and thermally matched materials to maximize power evacuation while minimizing thermal stress

- Higher Working Currents and Lower Conduction Losses– replaces wire bonds with heavy gauge, high current handling heatsunk copper traces

- Weight Reduction – uses lightweight materials

- Simplified Next Level Assembly – terminations optimally located to interface with the system

- Any Size or Shape – takes full advantage of available system real estate, including 3D capability

- Any Terminal Type– high power threaded, soldered male/female turrets, flex cable, power bar, etc; mix & match different control and power connections

- Repairable / Reworkable

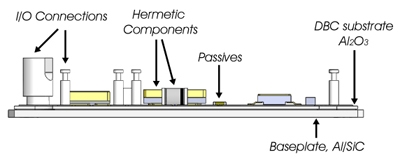

Material Technology

- Hermetic SMT components

- DBC substrate, typ 5 - 8 mil thick copper

- Ceramic: typically alumina (Al2O3); Aluminum Nitride (AlN) for thermally challenging applications

- Rugged I/O connections: typically Beryllium Copper (BeCu) for enhanced hardness

- Baseplate: typically AlSiC, used as an electrically isolated heat spreader and mechanical interface

- High voltage potting

Performance / Features

- High thermal conductivity

- Layout optimized for circuitry and I/O

- Includes passive components such as:

- Thermistors or current sense resistors

- Capacitors

- Inductors

- Thermal stress minimization via CTE matched materials

- Application specific solution

- Simplifies procurement with single item

Sedpack 2: RθJC = 0.7°C/W

| Substrate | AlN | Al203 |

| t | 0.025 in. | 0.025 in. |

| W | 0.315 in. | 0.315 in. |

| L | 0.315 in. | 0.315 in. |

| K | 170 W/m°K | 20 W/m°K |

| Thermal Resistance | 0.06°/W | 0.50°/W |

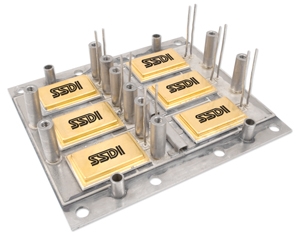

Examples of Power Modules

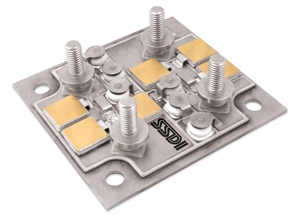

Battery Bypass Module

- Application: space / satellite

- 450 A / leg discharge, 50 A / leg charge

- AlSiC baseplate, CTE matched components

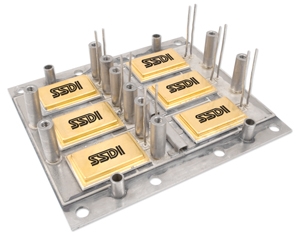

Three Phase IGBT Bridge

- Application: launch vehicle

- 600 A, 600 V

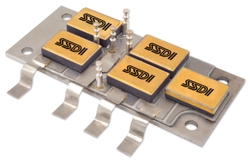

Four Cell High Current Schottky Power Diodes

- High current Schottky centertap assembly

- AlSiC baseplate, CTE matched components

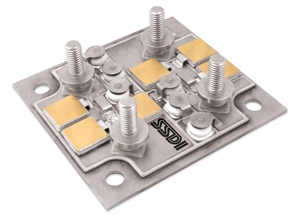

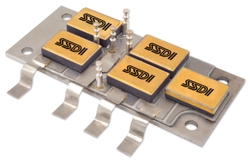

Battery Bypass Module

- Rad hard half bridge MOSFET

- Application: space level / non-repairable

- Two power MOSFETs in parallel for current enhancement

- Dual independently controlled channels

- 125 W, 200 V DC

- 27 A steady state current, 65 A peak current

- AlSiC baseplate, CTE matched components

Battery Charge Power Module

- Application: space

- 60 A, 1000 V for use with NiH2 batteries, hermetically sealed

- VR = 1 kV, IO = 60 A

- AlSiC baseplate

- Temperature range: -65°C to +150°C

- 27 A steady state current, 65 A peak current